Zinc Oxide Recycling with Waelz Kiln Technology

At MP Group, we leverage the advanced Waelz Kiln technology for zinc oxide recycling, a process that efficiently handles more than 80% of the world’s recycled zinc waste materials, including electric arc furnace (EAF) dust, induction furnace (IF) dust, zinc slag, and zinc concentrate ore. The Waelz Kiln process is a well-established, energy-efficient, and robust method for treating zinc-containing materials and residues, making it a cornerstone of sustainable zinc oxide recycling.

The Need for Zinc Oxide Recycling

Historically, zinc-containing dust and sludges were often disposed of in landfills. However, over the past few decades, various extraction processes have been developed to recover valuable metals from these materials, drastically reducing waste. The steel industry alone produces approximately 10 million tons of EAF dust annually, containing around 2 million tons of zinc. Recycling this dust is essential not only for recovering zinc but also for minimizing environmental impact.

How Waelz Kiln Technology Works in Zinc Oxide Recycling

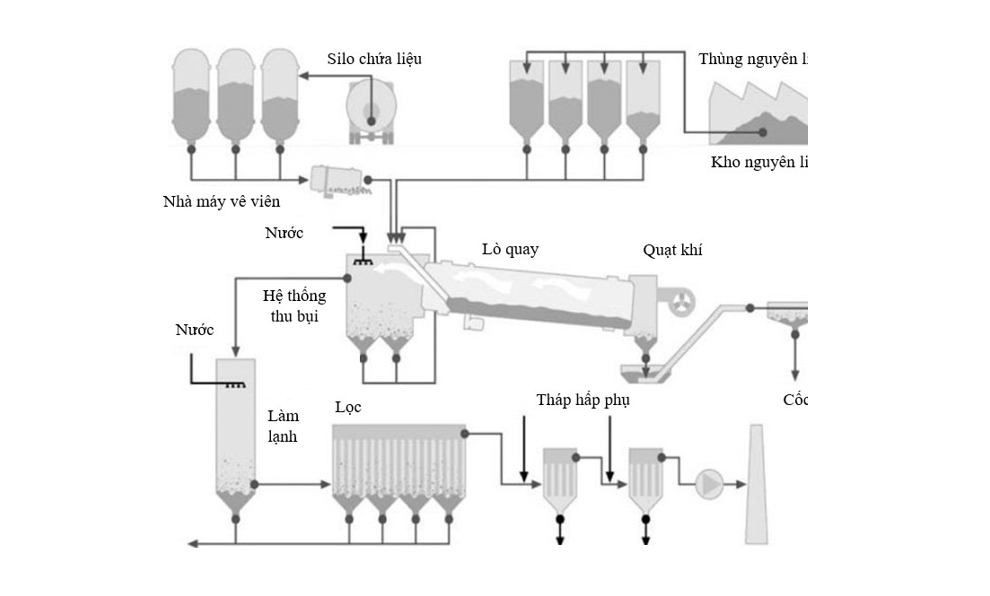

The Waelz Kiln technology utilizes a rotary kiln system where zinc-containing residues undergo reduction by carbon carriers. As the kiln rotates, the materials are heated to about 1200°C, causing the zinc and lead to sublimate and re-oxidize. These metals are then transported and separated in downstream gas purification systems. The entire process is supported by the addition of lime for slag formation, creating a robust system for extracting valuable zinc oxide from waste materials.

Before entering the Waelz Kiln, materials like EAF dust and sludge, which contain around 74% zinc by weight, are homogenized and pelletized. The pelletizing process enhances the transport, storage, and utilization properties of these materials, making them easier to handle throughout the recycling process. The refined pellets provide improved reintroduction into metallurgical processes, ensuring efficient and effective recycling.

(This video is property of CoGreenTech S.A.)

The Waelz Kiln Process: A Step-by-Step Overview

- Material Transportation: EAF steel dust is transported to the zinc oxide recycling plant by road or rail.

- Material Preparation: Feed materials arrive in dry, compact-moist, or pelletized form. Dry dust is stored in silos, while moist materials, coarse fluxes, and coke are stored in dedicated boxes.

- Kiln Processing: The Waelz Kiln, typically 55 meters long and 4 meters in diameter, is slightly inclined and rotates at about 1.0 rpm. As the material moves through the kiln, it is dried and preheated by kiln gases flowing counter-currently.

- Reduction Zone: At approximately 1200°C, the reduction of metal oxides occurs, vaporizing zinc into the gas cleaning system. Zinc is then re-oxidized in the kiln’s atmosphere, operated with excess air.

- Off-Gas Treatment: Chlorine, alkalis, and heavy metals volatilize, and the dust-laden off-gas is treated in a downstream system. Coarse particles are separated in a dust settling chamber and returned to the kiln, while hot off-gas is cooled, and Waelz Zinc Oxide is separated using a high-efficiency collector.

- By-Product Management Waelz Iron Product (WIP), a co-product, can be utilized in road and civil construction, cement manufacturing, or further processed to enhance its iron content.

- Environmental Compliance: The cleaned, dust-free off-gas meets stringent environmental standards, ensuring a sustainable and compliant recycling process.

- Final Product: The primary output zinc oxide recycling – Waelz Zinc Oxide, is delivered to zinc smelters for the production of pure zinc.

Advantages of Waelz Kiln Technology in Zinc Oxide Recycling

Waelz Kiln technology has been continuously refined over the past 80 years, with MP Group pioneering further advancements to create one of the most efficient and environmentally friendly zinc recycling systems globally. The technology is especially well-suited to meet the rising demands of global environmental regulations due to its energy efficiency and minimal environmental footprint.

Why Choose MP Group for Zinc Oxide Recycling?

MP Group stands out as a leader in the field of zinc oxide recycling with the best-designed Waelz Kiln system available. Our commitment to innovation, energy efficiency, and compliance with environmental laws ensures that we offer our clients the most effective solutions for recycling zinc-containing materials. By partnering with us, you can be assured of a sustainable, reliable, and advanced approach to zinc recycling.

For more information or to discuss potential partnerships, please contact our team of experts. We are dedicated to providing customized solutions that meet your specific needs in zinc oxide recycling and zinc-containing material management.