Introduction to Rotary Hearth Furnace (RHF) Steel Dust Recycling Technology

The steel industry generates vast amounts of waste materials, such as Electric Arc Furnace (EAF) dust, that contain valuable metals like zinc, iron, and lead. Instead of disposing of this waste in landfills, recycling technologies like the Rotary Hearth Furnace (RHF) offer a sustainable solution. RHF technology is revolutionizing the way steel producers handle metallurgical waste by efficiently recovering zinc and iron from EAF dust and other fine particulates.

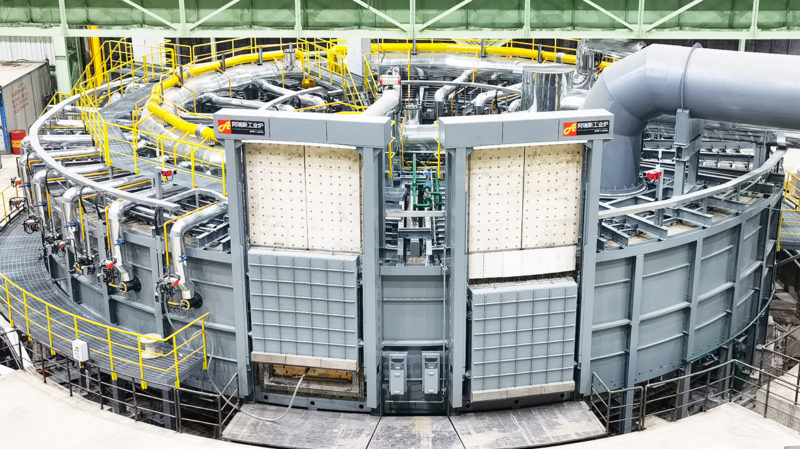

How Rotary Hearth Furnace (RHF) Works

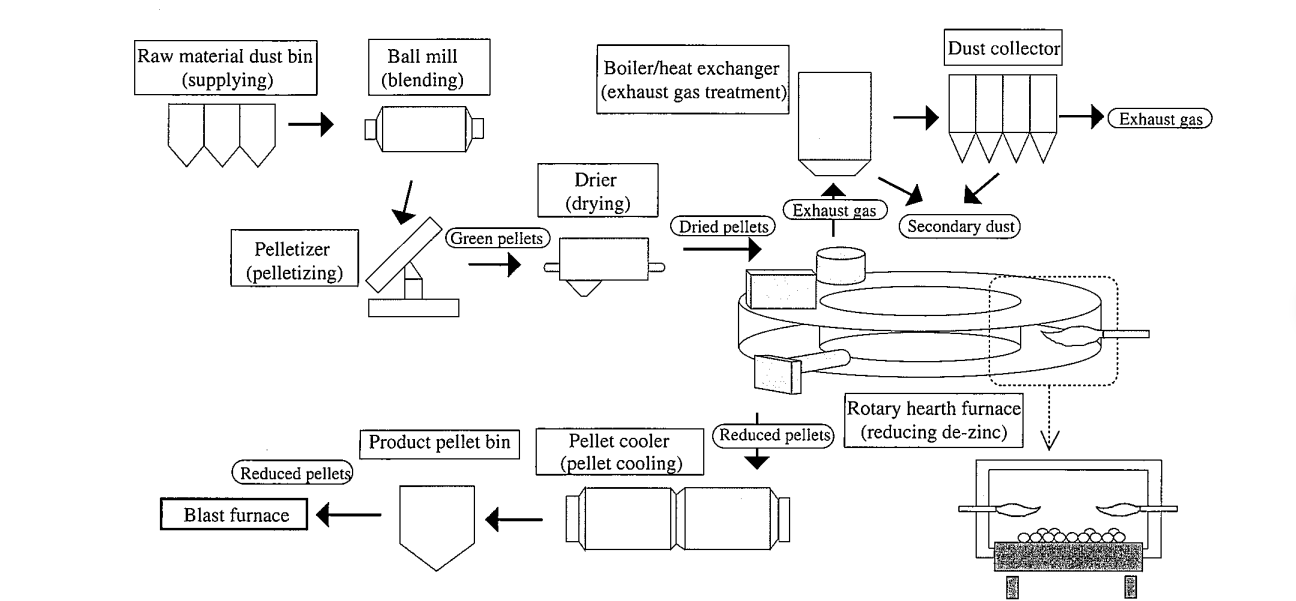

The RHF is a circular furnace designed to process metal-bearing dust, sludge, and other fine waste materials. Here’s a step-by-step overview of how RHF technology operates:

- Material Preparation: EAF dust is mixed with a carbon-based reductant, such as coal or coke. This mixture is then pelletized to improve the material’s handling and reactivity inside the furnace.

- Heating and Reduction Process: Inside the RHF, the material is heated to extremely high temperatures (up to 1,400°C). The carbon in the mixture reacts with zinc, iron, and lead oxides, reducing them to their metallic forms.

- Metal Recovery:

- Zinc and Lead Recovery: Zinc and lead vaporize during the heating process and are collected as zinc oxide and lead oxide in the off-gas system.

- Iron Recovery: The solid iron remains in the furnace as Direct Reduced Iron (DRI), which can be reused in steel production.

Benefits of Rotary Hearth Furnace (RHF) Dust Recycling Technology

- Efficient Metal Recovery: RHF technology enables steel plants to recover both zinc and iron from EAF dust, reducing waste and maximizing resource utilization.

- Environmental Sustainability: By recycling hazardous EAF dust, RHF minimizes landfill disposal and mitigates the environmental impact of steel production.

- Cost-Effective: The RHF can process a wide range of fine particulates, making it an economical choice for steelmakers who want to recover valuable metals from waste materials.

Why Choose RHF for EAF Dust Recycling?

Steel producers are increasingly turning to Rotary Hearth Furnace (RHF) technology as a sustainable and profitable solution for recycling EAF dust. By recovering zinc and iron, RHF not only reduces the cost of raw materials but also contributes to a circular economy, where waste is transformed into valuable resources.

Conclusion

With the steel industry facing increasing pressure to adopt sustainable practices, Rotary Hearth Furnace (RHF) technology offers a proven method for recycling dust and other waste materials. It enhances metal recovery, reduces environmental impact, and helps steel producers meet both regulatory and economic goals. If you’re looking for an efficient way to recycle EAF dust, RHF technology is the solution you need.