Complete Guide to Waelz Zinc Oxide recycling: Processes, Benefits and Applications

Introduction to Waelz Zinc Oxide recycling

MP Group offers innovative solutions for Waelz Zinc Oxide recycling, utilizing environmentally friendly processes to recover this valuable material for various industrial applications while minimizing waste.

What is Zinc Oxide and Its Importance in Industry

Chemical Properties and Uses of Zinc Oxide: Zinc oxide (ZnO) is a versatile inorganic compound with notable chemical properties, such as a wide bandgap and high thermal conductivity. It is commonly used as a white pigment, in sunscreens for UV protection, and as a semiconductor in electronic devices.

Industries Relying on Zinc Oxide: Various industries, including rubber manufacturing, paints, cosmetics, and electronics, depend heavily on zinc oxide. Its unique characteristics make it essential for producing high-performance materials in these sectors.

The Need for Waelz Zinc Oxide recycling

Environmental Impact of Zinc Oxide Waste: Improper disposal of zinc oxide waste can lead to significant environmental pollution, including soil and water contamination, which poses risks to ecosystems and human health.

Economic Benefits of Recycling: Recycling zinc oxide not only reduces waste but also generates economic value by transforming waste into a resource, ultimately lowering production costs for manufacturers.

Conservation of Natural Resources: Recycling zinc oxide conserves natural resources by reducing the demand for virgin materials, thereby promoting sustainability and responsible resource management.

Sources of Recyclable Zinc

Industrial Waste Streams: Many industries produce zinc as a by-product, especially in metal manufacturing such as stell mills, galvalnizing, lead smelting providing a rich source for recycling.

End-of-Life Products Containing Zinc: Products such as electronics devices, battery, automotive components, zinc metalic structure… often contain zinc oxide, and recycling these end-of-life products can recover valuable zinc oxide for reuse.

Mining and Metallurgical By-Products: Mining operations and metallurgical processes frequently generate zinc oxide waste, which can be effectively recycled to recover zinc.

Zinc Oxide recycling Processes

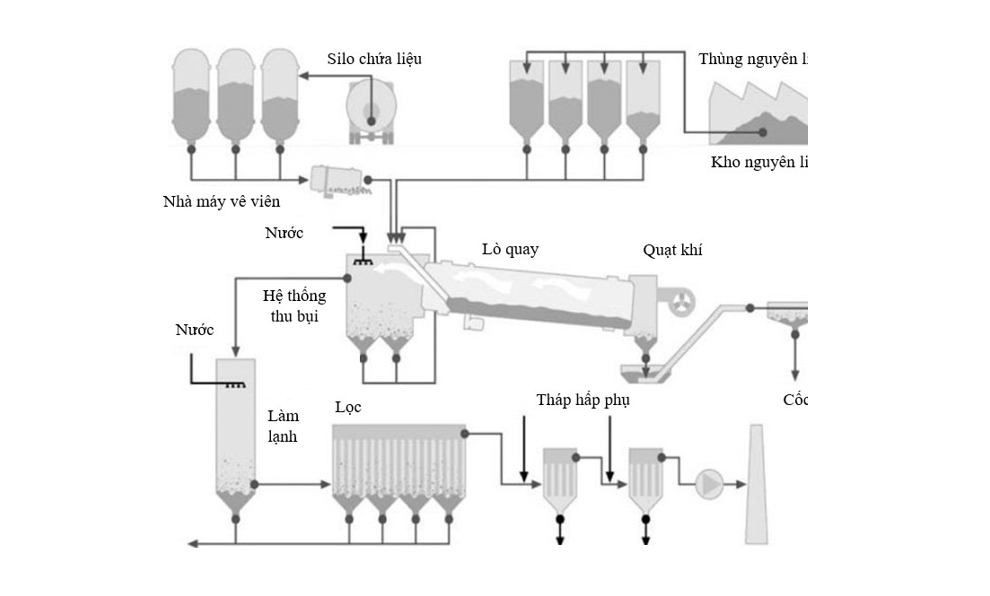

Pyrometallurgical Recycling Methods: This method involves high-temperature processes to recover zinc oxide from waste, often utilizing rotary kilns and furnaces to facilitate recovery.

Hydrometallurgical Recycling Techniques: Hydrometallurgy employs aqueous chemistry to extract zinc oxide from various waste streams, allowing for a more environmentally friendly approach compared to traditional methods.

Chemical Precipitation Processes: In this method, chemical reactions are utilized to precipitate zinc oxide from solution, enabling the recovery of high-purity zinc.

Electrolytic Recovery Methods: Electrolytic processes use electrical current to extract zinc from solutions, offering an efficient method for recycling zinc oxide.

electrolytic recovery of zinc, allowing for high-efficiency extraction from waste streams.

Quality Control in Production

Purity Standards for Recycled Zinc Oxide: Maintaining high purity standards is essential for ensuring the quality of recycled zinc oxide for industrial applications.

Testing Methods and Equipment: Rigorous testing methods, including spectroscopy and chromatography, are employed to verify the purity of recycled zinc oxide.

Certification and Compliance Requirements: Compliance with international standards and certifications is necessary to ensure that the recycled material meets industry requirements.

Economic Advantages of Zinc Oxide recycling

Cost Savings for Manufacturers: Recycling offers manufacturers significant cost savings by providing a cheaper alternative to virgin materials.

Creation of New Job Opportunities: The recycling industry fosters job creation in collection, processing, and quality control sectors.

Reduced Dependence on Raw Material Imports: Promoting local recycling helps countries reduce their reliance on imported raw materials, enhancing economic resilience.

Challenges in Zinc Oxide recycling

Contamination Issues in Waste Streams: Contamination can hinder the recycling process, making it essential to develop effective sorting and processing techniques.

Technological Limitations: Current technologies may not be sufficient for efficiently recycling all types of zinc oxide waste, necessitating ongoing research and development.

Market Fluctuations for Recycled Materials: The market for recycled zinc oxide can be volatile, impacting the economic viability of recycling initiatives.

Future Trends

Advancements in Recycling Technologies: Ongoing innovations in recycling technologies will enhance efficiency and purity, making recycling more attractive.

Expanding Applications for Recycled Zinc Oxide: As industries seek sustainable solutions, the applications for recycled zinc oxide are expected to grow.

Regulatory Changes Impacting the Industry: Emerging regulations will likely drive further adoption of recycling practices, promoting sustainable material management.

Best Practices for Implementing Zinc Oxide recycling

Establishing Efficient Collection Systems: Creating robust collection systems is crucial for maximizing the recovery of recyclable zinc oxide from various sources.

Optimizing Processing Techniques: Continuous improvement in processing techniques will enhance the efficiency and effectiveness of Waelz Zinc Oxide recycling.

Ensuring Product Quality and Consistency: Maintaining high standards of quality and consistency in recycled zinc oxide is essential for its acceptance in industrial applications.

Case Studies: Successful Programs

Industrial Partnerships for Waste Reduction: Collaborative efforts between industries can lead to innovative recycling solutions and significant waste reduction.

Government-Supported Recycling Initiatives: Governments play a vital role in promoting recycling through policies, funding, and awareness campaigns.

Innovative Recycling Projects in Developing Countries: Emerging economies are exploring creative recycling solutions that cater to local needs and capabilities.

Considerations for Implementing Zinc Oxide recycling

Ensuring Safety During Processing: Safety is paramount in the recycling of zinc oxide, necessitating appropriate preventive measures.

Complying with Environmental Regulations: Adhering to environmental regulations is essential to protect public health and ecosystems.

Maintaining Quality of Recycled Products: Ensuring the quality and consistency of recycled products is crucial to meet market demand.