Understanding Electric arc furnace Dust (EAFD): Production, Challenges, and Recycling Solutions

Electric Arc Furnace (EAF) dust, a by-product of steel manufacturing in electric arc furnaces, is a significant material in the recycling and metals industry. At MP Group, we provide insights into the production, challenges, and effective recycling solutions for EAF dust, emphasizing our commitment to sustainability and resource efficiency.

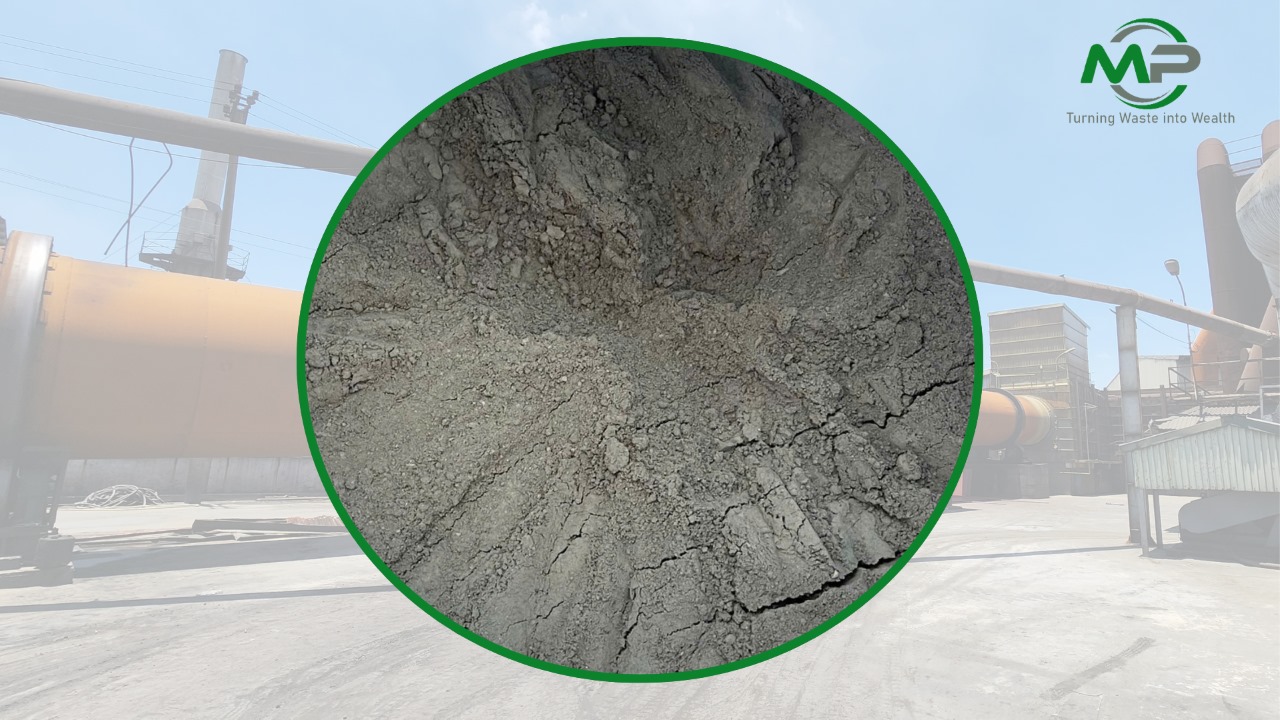

Electric Arc Furnace dust is the fine particulate matter collected during the steel production process in electric arc furnaces. This dust is generated from the melting and refining of steel scrap and other raw materials, which results in a mixture of various metal oxides, sulfides, and other chemical compounds.

What generate Electric arc furnace dust?

- Steel Production Process:

- In the electric arc furnace, steel is produced by melting scrap steel using electrical energy. The process involves high temperatures that cause the formation of various gases and dust particles.

- Dust Collection:

- Dust and fumes produced during this process are captured using advanced filtration systems to prevent environmental contamination. The collected dust is referred to as EAF dust.

Composition

- Zinc: One of the major components, often 20-35%Zn.

- Lead Compounds: May be present depending on the source materials, typical 0.5-3%.

- Iron: Includes iron oxides around 25-35%.

- Chemical Compounds: Such as chlorides and sulfides.

Challenges

- Environmental Impact:

- Electric Arc Furnace dust contains hazardous materials, making its management and disposal a critical environmental concern. Improper handling can lead to soil and water contamination.

- Resource Recovery:

- Extracting valuable metals like zinc and lead from EAF dust requires efficient recycling technologies to ensure resource recovery and reduce waste.

- Regulatory Compliance:

- Strict regulations govern the handling and recycling of Electric Arc Furnace dust to minimize environmental and health risks.

MP Group’s Commitment to Recycling

At MP Group, we are dedicated to addressing the challenges of EAF dust through innovative recycling solutions and sustainable practices. Our use of Waelz kiln technology reflects our commitment to effective resource recovery and environmental protection.

Partner with Us

Electric Arc Furnace Dust: A Challenging Issue, Now with an Optimal Solution

MP Group is proud to be a pioneer in recycling EAFD in Vietnam. With cutting-edge technology and a team of experienced experts, we have successfully transformed this waste into valuable products, contributing to environmental protection and sustainable development.

Why choose MP Group?

- Advanced Technology: Our state-of-the-art equipment ensures efficient and safe recycling processes.

- Expert Team: Our team of engineers and experts provides the best advice and support to our customers.

- Professional Processes: We adhere to international standards to ensure the quality of our products.

- Environmental Protection: All of our activities are focused on protecting the environment and promoting sustainable development.

- Cost Savings: Reduce waste disposal costs and maximize resource utilization.

- International Standards: Our products meet high-quality standards and meet market demands.

Act now!

Don’t miss out on the opportunity to contribute to a greener future. Contact us today for consultation and cooperation. Together, let’s build a cleaner and more beautiful tomorrow.